Steelmaking is a craft that dates back millennia, yet its importance hasn’t waned. Today, it plays a pivotal role in infrastructure, transportation, and countless other sectors. At the heart of this process is the transformation of iron ore into various steel products, such as I-beams, used in construction. Let’s embark on the journey of steel – from its rawest form to its sturdiest structures.

“Steelmaking is a testament to human ingenuity, turning the earth’s raw materials into the towering structures that punctuate our skylines.”

Mining the Ore: The First Step

The story begins in the depths of the earth, where iron ore is extracted. Countries like Australia, Brazil, and China lead in this mining endeavor, providing a significant portion of the world’s iron ore.

The Smelting Process: Blast Furnaces in Action

Once extracted, the iron ore is then smelted in blast furnaces. Here, the ore is combined with coke and limestone, undergoing a chemical transformation that produces molten iron.

Refining the Metal: Basic Oxygen Furnaces

While the molten iron produced is rich in carbon, it’s not yet the steel we recognize. The metal is further refined in Basic Oxygen Furnaces, where oxygen is blown through the molten iron, reducing its carbon content and turning it into steel.

Casting and Rolling: Giving Steel Its Shape

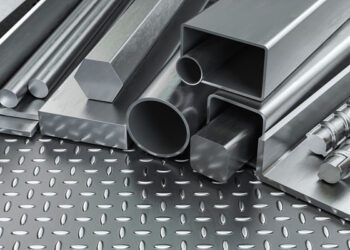

After the refining process, the molten steel is cast into large slabs or billets. These are then heated and passed through rolling mills, which shape the steel into desired forms, like sheets or rods.

The Creation of I-Beams: Precision and Purpose

I-beams, characterized by their I-shaped cross-section, are vital in construction. The steel is specifically rolled to produce these beams, ensuring they possess the necessary strength and flexibility to support large structures.