The steel manufacturing industry stands as one of the essential backbones of modern civilization. Without steel, our buildings, cars, and countless other products would be impossible to produce. But how exactly is steel made? Let’s delve deep into this incredible process.

“Steel manufacturing isn’t just a process; it’s an art that has been refined for millennia, turning raw materials into the sturdy alloy we rely upon daily.”

The Raw Material: Iron Ore

The journey of steel starts with iron ore. Mined primarily in countries like Australia, Brazil, and China, this ore serves as the primary raw material in steel production.

From Blast Furnaces to Steel

Traditionally, the blast furnace method was used, wherein iron ore is melted with coke and limestone to produce molten iron. This iron is then refined further to produce steel.

Modern Steel-Making Methods

With advancements in technology, methods like Electric Arc Furnace (EAF) have become popular. Using recycled steel scrap, the EAF process is more environmentally friendly and efficient.

The Importance of Alloying

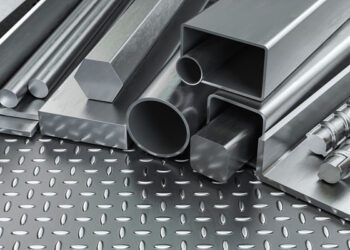

Steel isn’t just iron. Alloying elements like carbon, manganese, and nickel are added to provide steel with its unique strength, flexibility, and resistance properties.

Environmental Concerns and Sustainable Practices

The steel industry has faced criticism due to its environmental impact. However, modern practices emphasize sustainability, with a focus on recycling and reducing emissions.