The steel industry, with its rich heritage of innovation, has been at the forefront of adopting modern technologies. Among these, robotics and Artificial Intelligence (AI) have started to reshape the very essence of steelmaking. From improving safety to augmenting precision, the age-old anvils are getting a futuristic makeover.

“In the dance of fire and metal, robots and algorithms have taken the stage, ushering in a new era of steel production.”

Historical Context: Steel and Automation

Automation in steel mills isn’t a novel concept. As early as the 20th century, advancements like continuous casting and automated quality checks began streamlining the production process, setting the stage for the modern technological influx.

Robotics in Modern Steel Mills

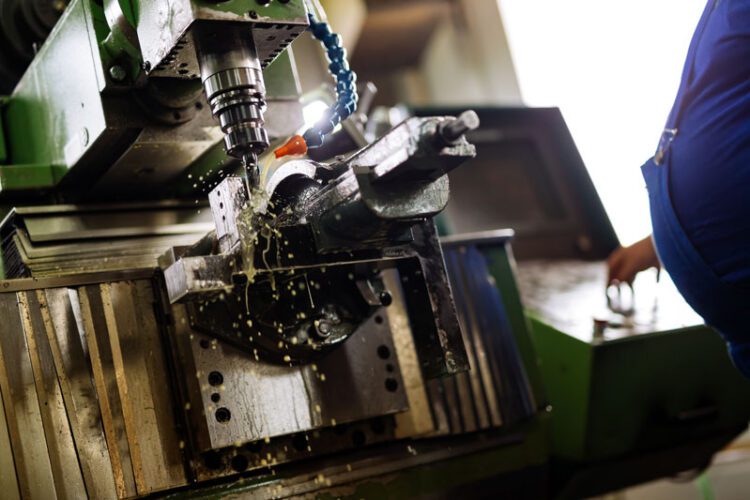

Robots have found several roles in steel manufacturing:

Handling and Transport: Moving heavy steel ingots, slabs, or other materials efficiently and safely.

Welding and Assembly: Ensuring precise and consistent joins in steel parts.

Maintenance and Inspection: Using drones or robotic arms for inspecting hard-to-reach areas, reducing downtime and increasing safety.

AI-Driven Innovations in Steel Production

Artificial intelligence brings a new dimension to steelmaking:

Predictive Maintenance: Using data analytics to predict equipment failures before they occur.

Quality Control: Implementing machine learning algorithms for real-time quality checks and adjustments.

Supply Chain Optimization: AI models analyzing market demands, raw material prices, and production rates to optimize operations.

Benefits of Technological Integration

The amalgamation of robotics and AI in steel mills leads to:

Enhanced Safety: Reducing human exposure to hazardous areas.

Increased Productivity: Faster operations with minimal errors.

Cost Savings: Optimizing resource usage and reducing waste.

The Road Ahead: Challenges and Opportunities

While the integration promises vast potential, challenges like the need for skilled workers, high initial investments, and cybersecurity concerns arise. However, as technology continues to evolve and the industry adapts, the future of steel production appears brighter, smarter, and more efficient than ever.